Ship operators invited to join ‘stethoscope for cylinders’ trial to prevent two-stroke engine scuffing

CM Technologies (CMT), a leader in advanced condition monitoring solutions, is calling on shipowners and managers to join collaborative trials designed to capture vital data on one of the shipping industry's most costly problems: cylinder liner scuffing in two-stroke engines.

Scuffing, a form of sudden severe wear, can result in catastrophic engine damage and vessel downtime. And while it’s a well-known issue, typically affecting large two-stroke diesel engines found on bulkers, tankers, and large container ships, the root causes are difficult to pin down. Operators, OEMs, and service providers have long struggled to predict or prevent the phenomena.

Germany-based CMT, however, has developed a system that can alert operators to early onset cylinder damage, but see seeks trial partners for critical data gathering aimed at validating the sensor’s predictive capabilities and to prevent engine damage before it occurs.

“Scuffing is a silent killer. It can occur suddenly, and the damage can be extensive,” said Uwe Krüger, Managing Director at CM Technologies. “Despite the prevalence of this issue, even engine manufacturers don’t fully understand why it happens. What we do know is that it’s linked to a combination of factors, like lubrication failure, drastic load changes, recent overhauls, amongst other things. Our goal is to better understand the acoustic fingerprint of scuffing so we can prevent failures before they happen.”

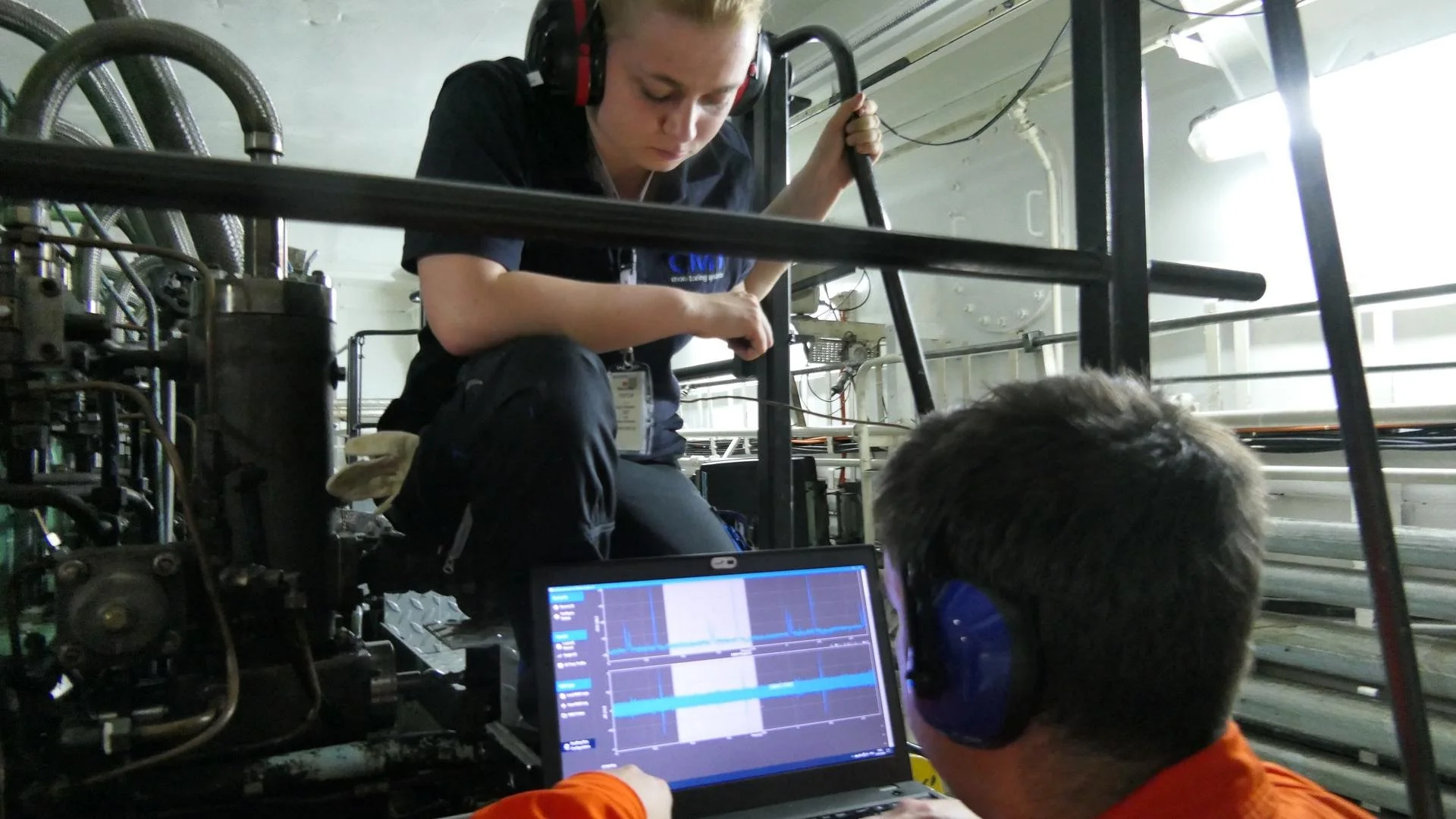

CMT’s recently developed Scuffing Sensor system – a ‘stethoscope for cylinder liners’ – uses high-frequency acoustic emission (AE) technology to detect the earliest signs of friction and wear from outside the cylinder.

Unlike other methods that rely on visual inspection or oil analysis performed weeks apart, this approach captures real-time acoustic data without interrupting engine operation. By identifying wear-related noise patterns, the system provides a potential early-warning signal before damage occurs.

Trial partners are invited to deploy the system onboard vessels equipped with two-stroke diesel engines. Ideally, these vessels will call at ports in Northern Europe, Germany, the Netherlands, Belgium or France, where CMT engineers can easily access them to install and retrieve data-logging equipment.

The system itself is unobtrusive, requires no modifications to engine internals, and is non-invasive. Mounted externally using magnetic brackets, the sensors require no disassembly, no drydock visit and no interruption to the ship’s voyage.

“There’s no need to open the engine or stop operations. The sensor system is magnetic, sits externally on the cylinder, and records data quietly in the background,” said Krüger “We’re looking for operators that will let us place this technology onboard for one to three months. The process is simple, and the benefits could be significant.”

By participating in the trials, ship operators and managers stand to gain early insight into the scuffing risks on their engines, while helping CMT further develop the breakthrough diagnostic tool for the wider industry.

“We’re not asking shipowners to shoulder any risk, just to let us listen to their engines. Together, we can create something that protects engines, saves money, and sets a new benchmark for condition-based maintenance.”

Shipowners or managers interested in participating in the scuffing detection trials are invited to contact CM Technologies at info@CMTechnologies.de